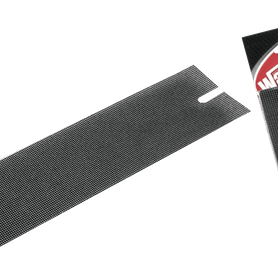

Pferd Mounted Flap Wheel Fan Grinders Zirconia Alumina 30x20mm Pack of 10

Specially designed for work on stainless steel (INOX) and high-temperature-resistant alloys. Active grinding additives in the coating significantly improve stock removal, prevent clogging and result in cooler grinding.

Abrasive: Zirconia alumina Z-COOL

PFERD provides mounted flap wheels / Fan Grinders with various

- grit sizes,

- abrasives and

- dimensions.

Advantages:

- High flexibility

- High stock removal due to the aggressive coated abrasive

- Carrier material wears off uniformly and without residue on the workpiece surface, meaning that sharp abrasive grit is exposed at all times

- Due to the flat cast core construction, the face of the mounted flap wheels can be used to work very close to edges and in corners

- Fine grinding on radii in tool and mould construction

- Machining of small and hard-to-reach areas in apparatus engineering and tank construction

- Machining of fittings made out of nonferrous and light metals

- Grinding of turbine blades in aircraft engine construction and repair

- Mounted flap wheels achieve their best performance at a recommended cutting speed of 15Ð20 m/s. This provides an ideal compromise between stock removal, surface quality, thermal load on the workpiece and tool wear.

- Flexible shafts, electric and air-powered straight grinders can be used as tool drives

- Use grinding oil that is suitable for the material in order to significantly increase the tool life and the abrasive performance of the tools.

- Tool wear and thermal load: The reduction of the contact pressure and the peripheral speed, together with the addition of grinding oil, reduce tool wear and the thermal load on the workpiece.

- Stock removal: An increase in stock removal should be attained by using a coarser grit size rather

- than by increasing the contact pressure in order to prevent unnecessary tool wear and thermal load on the workpiece.

- Surface roughness: The increase in cutting speed results in a slightly finer surface. By increasing the

- contact pressure, the surface becomes slightly rougher. The softer the material to be worked, the rougher the surface (if the same grit size is used).

- For safety reasons, it is imperative to remain within the stated maximum permitted rotational

- speed at all times

- Safety is only guaranteed if:

- The clamping depth is at least 15 mm

- The specified maximum rotational speed for unsupported shank lengths is not exceeded

Details

- Item: Fan Grinders - Flap Wheels

- Head Size Dia x Length: 30 x 20mm

- Grit: 60, 80

- Shank: 6mm

- Abrasive: Zirconia alumina Z-COOL

- Quantity: Pack of 10